Performing a safety check on a SCOTT self-contained breathing apparatus (SCBA) is crucial for ensuring the equipment's reliability and the safety of its users. Here are the detailed steps to conduct a thorough SCBA safety check:

-

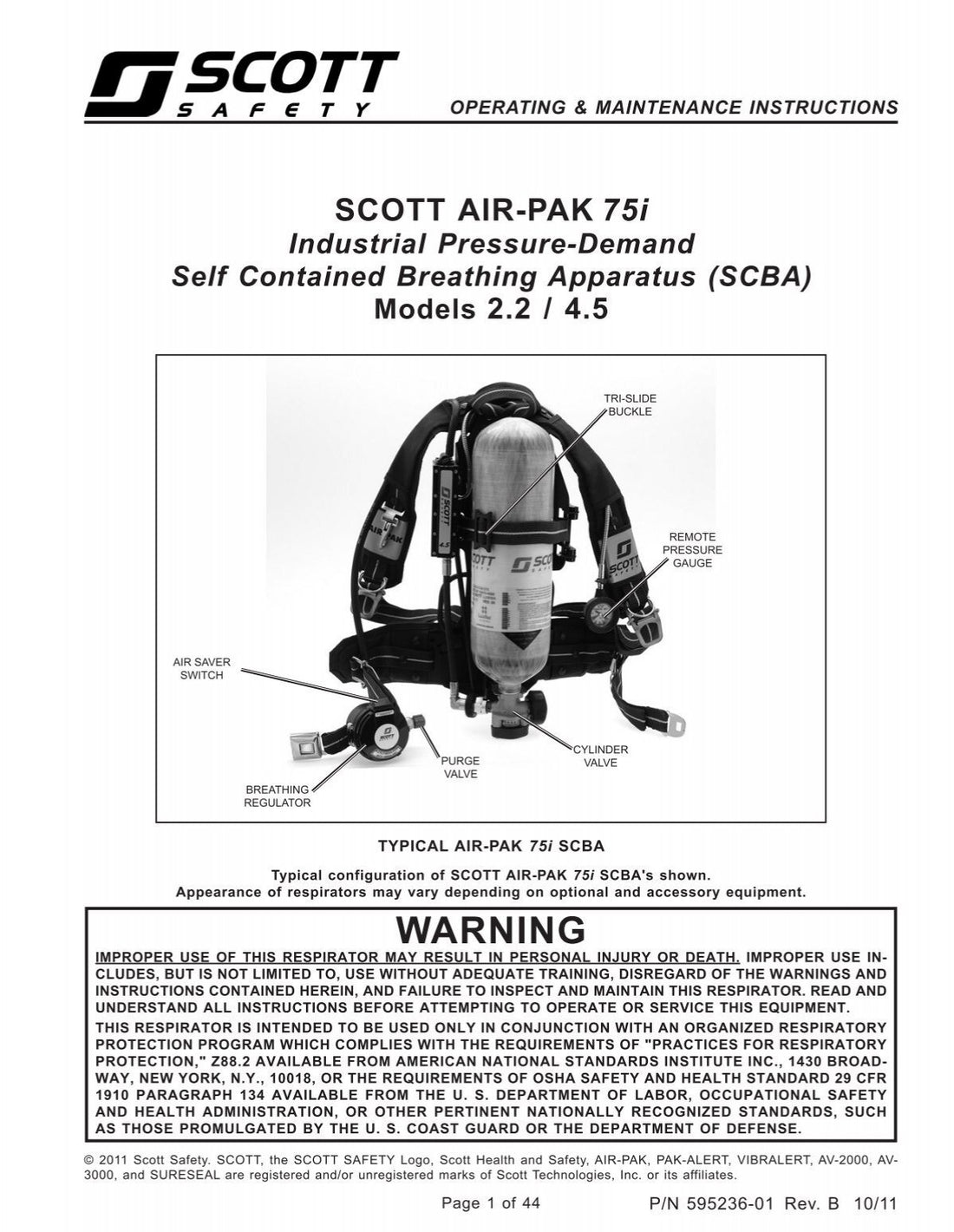

Visual Inspection:

-

Harness and Straps:

- Inspect the harness and straps for any signs of wear, cuts, or damage.

- Ensure all buckles and adjustments work properly.

-

Cylinder and Valve:

- Check the cylinder for dents, cracks, or other damage.

- Ensure the valve operates smoothly without leaks.

-

Regulator and Hoses:

- Inspect the regulator and hoses for signs of wear, cracks, or damage.

- Ensure all connections are secure and there are no leaks.

-

Harness and Straps:

-

Cylinder Check:

-

Pressure Check:

- Ensure the cylinder is fully charged. The pressure should be within the recommended range (typically 90-100% of the rated pressure).

- If the cylinder is low, refill it according to the manufacturer's guidelines.

-

Hydrostatic Test Date:

- Check the hydrostatic test date to ensure the cylinder is within the valid test period.

-

Pressure Check:

-

Regulator and Gauge Check:

-

Primary Regulator:

- Attach the regulator to the cylinder and ensure it seats properly.

- Open the cylinder valve slowly and check for any leaks.

-

Pressure Gauge:

- Verify that the pressure gauge matches the cylinder pressure.

- Ensure the gauge is not damaged and reads accurately.

-

Primary Regulator:

-

Low-Pressure Alarm:

-

Activation Check:

- Slowly depressurize the system by turning off the cylinder valve and opening the regulator purge valve.

- Verify that the low-pressure alarm activates when the pressure drops to the alarm threshold (typically 25% of full pressure).

-

Activation Check:

-

Facepiece Inspection:

-

Visual Check:

- Inspect the facepiece for cracks, scratches, or other damage.

- Ensure the lens is clear and the seal is intact.

-

Straps and Head Harness:

- Check the straps and head harness for any signs of wear or damage.

- Ensure all adjustments work properly and the straps are not twisted or frayed.

-

Visual Check:

-

Donning the SCBA:

-

Proper Fit:

- Don the SCBA according to the manufacturer's instructions.

- Ensure the harness fits snugly and the facepiece seals properly on the face.

-

Breathing Test:

- Take a few breaths to ensure the air flows smoothly and there are no restrictions or leaks.

- Verify that the exhalation valve works properly and the mask does not fog up.

-

Proper Fit:

-

Functional Test:

-

Demand Valve:

- Check the operation of the demand valve by taking a deep breath. The valve should activate and provide air without delay.

- Ensure the valve closes properly when not in use.

-

Bypass Valve:

- Test the bypass valve by turning it on and off. Ensure it provides a steady flow of air when activated.

-

PASS Device:

- Activate the PASS (Personal Alert Safety System) device and ensure it functions correctly.

- Verify that the alarm sounds if the device is not moved for a specified period (usually 20-30 seconds).

-

Demand Valve:

-

Documentation:

-

Record Keeping:

- Document the results of the safety check, including any issues found and corrective actions taken.

- Ensure the inspection log is updated and accessible for future reference.

-

Record Keeping:

Performing these steps regularly ensures that your SCOTT SCBA is in optimal condition and ready for use in emergency situations. Always refer to the manufacturer’s manual for specific guidelines and recommendations tailored to your SCBA model.